| Processing size | 1300mm*2500mm*150mm |

| Machine structure | Thick wall square steel |

| Spindle speed | 6000-18000rpm/min |

| Processing speed | 8m-15m every minute |

| Tool | Ф3.175mm---Ф12.7mm |

| Repeat positioning | ±0.05mm |

| Weight | 1500kg |

| Dimension | 2400mm*3350mm*1900mm |

| Original electrical appliance | Haipu Monte frequency frequency |

| Appendix | 7.5KW Water circulation vacuum pump |

| Panel fixing method | Vacuum adsorption, automatic positioning cylinder |

| Dao Database | Random switch 12/16/20 disk in the knife |

| The maximum of the knife handle | 12.7 mm |

| This knife | Automatic pairing |

| Tablet structure | Seven -zone vacuum adsorption |

| Way of working | 1.5 KW Pure servo |

| Maximum carving | 8-50 m/min |

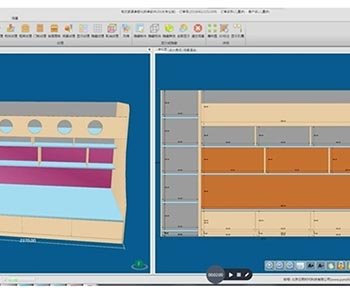

| Intelligent template production, computer drawing, software comes with a large number of templates, simple operation and many types of production. |

| Intelligent typography, improve the utilization rate of board, and save costs. |

| Import data, automatically cut the feeding, do not need extra manual operations, complex requirements can be completed in a short period of time. |

| Central dust and secondary dust removal device will maximize the collection of dust and ensure a good production environment. |

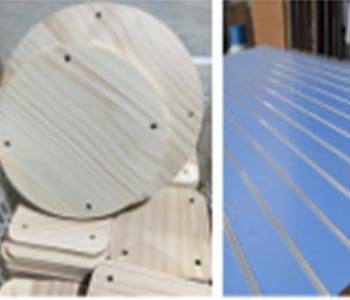

| Punning, slotting, opening, fast hollow speed, accurate size, saving labor. |

| The machine countertop uses thickened steel plates to ensure that the machine is not easy to deform, the carving flatness vertical is high, which increases the stability of the fuselage. |

|    |