| Semi -automatic band | Automatic single repair | Automatic dual majors | Automatic double triple slot | |

| Minimum effective width mm | 60 | 60 | 60 | 60 |

| Minimum processing surface length mm | 100 | 100 | 100 | 100 |

| Dimensions mm | 2700*900*1600 | 2700*900*1600 | 4200*900*1600 | 4900*900*1600 |

| Plate thickness mm | 8-50 | 8-50 | 8-50 | 8-50 |

| Highly sealing mm | 15-55 | 15-55 | 15-55 | 15-55 |

| Voltage V | 380 | 380 | 380 | 380 |

| Edge thickness MM | 0.3-3 | 0.3-3 | 0.3-3 | 0.3-3 |

| Work pressure MPa | ≥0.6 | ≥0.6 | ≥0.6 | ≥0.6 |

| PLC LCD operating panels clearly see the machine operation process, real -time monitoring, real -time adjustment, low speed 18m/min, medium speed 20m/min, tell 20m/min, speed adjustment, simple control. |

| With slotting device, it is used for side panel slotting, door sleeve, and back panel slotting, which is convenient and fast. |

| Use double milling cutter to tattoo marks, and the burrs are used for fine milling again to achieve better edge effects. |

| The glue cooker heating the solution, mesh spiral conveyor structure, evenly apply the glue on the plate and edge band. The strength is stronger, and there is no glue marks on the board. |

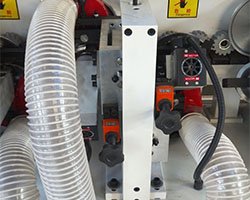

| Different air areas are regulated separately to make the edge more fit and smoother. |

| By automatic tracking and high frequency, the structure and other structures of the motor are guaranteed to ensure the smooth cut surface and the protection function of the head -headed board. |

| The rough knife is a flat knife to prevent the thin wood skin from broken, and it can also reduce the cutting rate and wear of the refined knife. |

| The polishing device is processed with cotton wentel fabrics, which can throw excess glue marks to make the edge surface layer smoother. |